Quick and simple loading from battery cages.

Strengths

|

|

All the answers for your questions.

|

|

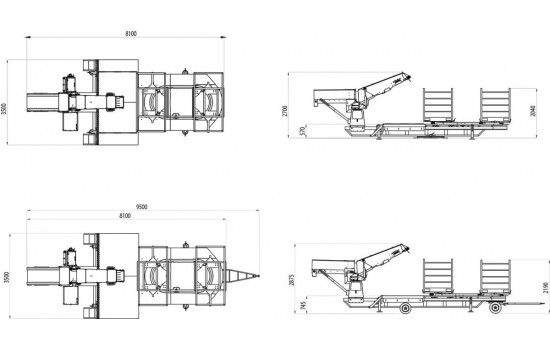

Technical data

MOTOR

Model: ElectricMaximum power: 7.5 kW

Functioning: 380 V

PERFORMANCE

Machine weight: 4,100 KgMachine set-up time: 15 minutes

Operator numbers: 2

Load quantity: from 10 to 24 tonnes/h

REFUELLING

Hydraulic tank: 150 lHYDRAULIC SYSTEM

Gears pump with fixed cylinder capacity:19cc + 8cc

Maximum pressure: 120 bar

STANDARD EQUIPMENT

Infeed beltIntegrated cage holder platform

Soft Start System: controls all the belts to gradually start, allowing the birds to keep their balance

OPTIONAL EXTRAS AND ACCESSORIES

Protection roof (for fixed version), standard connecting conveyor belt, hydraulic oil ATF XT for low temperaturesADDITIONAL INFORMATION

Frame: Hot-dip galvanised steel and stainless steelCleaning: High pressure air and water

Controls: IP 69 K