<p class="titoloCat"><strong>Load Quality,</strong><br />

the New Frontier. With blown air system.</p>

<p> </p>

<table border="0" cellpadding="0" cellspacing="0" width="960">

<tbody>

<tr>

<td>

<ol class="schedaDettagli">

<li><span>Load Quality</span><br />

Lower belts Speed. Wider belts. Smoother conveyoing. Gentle placement of the birds inside the containers. All resulted in better load quality with no compromises on loading speed.</li>

<li><span>Full focus on animal welfare</span><br />

<br />

Birds are loaded in a natural, stress-free manner, gently deposited into the drawers, with no direct contact from operators.</li>

<li><span>Addresses biosecurity issues</span><br />

<br />

The design has been optimized according to EHEDG (the European Hygienic Engineering and Design Group) guidelines. All components that come into contact with the birds are made out of either stainless steel or galvanized metal. Cages never come into contact with the litter.</li>

<li><span>Loading Speed</span><br />

<br />

From 8,000 to 12,000 animals per hour, or approximately 35,000-57,000 lb per hour.<br />

</li>

<li><span>Better working conditions for employees</span><br />

<br />

Easy to maneuver. Significant reduction in physical labour.</li>

<li class="liright"><span>Easy to clean</span><br />

<br />

Specifically designed to facilitate easy, quick and effective daily cleaning with only water and disinfectant with no compromises on biosecurity.</li>

<li class="liright"><span>Easy to use & Reduced Labor Cost</span><br />

<br />

Requires only 3-4 operators.Simple controls. Stable rubber tracks.Automatically loads birds to operator’s preset weight limit.</li>

<li class="liright"><span>Flexibility</span><br />

<br />

Loads any type of cage available in the US market.</li>

<li class="liright"><span>Durability & Reliability</span><br />

<br />

Designed on the field experience of more than 10Million working hours gained all-over the world</li>

<li class="liright"><span>Straightforward maintenance</span><br />

<br />

Clear and simple user manual, with explicit maintenance program outlined. Manual includes specific component breakdowns with diagrams of all parts. Easy access to core parts of the machine.</li>

</ol>

</td>

</tr>

</tbody>

</table>

<table border="0" cellpadding="0" cellspacing="0" class="domande" width="960">

<tbody>

<tr>

<td class="destraB">

<p class="titoloRosso"><strong>All the answers for your questions.</strong></p>

<p> </p>

<table border="0" cellpadding="0" cellspacing="10" width="100%">

<tbody>

<tr>

<td align="left" valign="top">

<p class="titoloRosso">IS APOLLO GENERATION 2 A QUALITY PRODUCT?</p>

Most definitely. With 40 years of experince and machines all over the world (over 90% market share wordwide) Apollo Gen2-B is the best solution to support your business. Apollo Gen2-B adheres to the strictest quality standards imposed by the leading food sector companies around the world.</td>

<td align="center" valign="top"><img alt="" src="image/icone/apollogeneration2.jpg" width="90" /></td>

</tr>

<tr>

<td align="left" valign="top">

<p class="titoloRosso">WHICH TYPES OF CONTAINERS CAN I USE?</p>

Any type. Apollo Gen2-B is suitable for the most common drawer systems and cages available on the market. The Apollo Gen2-B version has been optimized to work at its best in combination with the most common cages being used in the US market. Different types of containers can even be used during the same loading session: a simple computer setting is all that it takes.</td>

<td align="center" valign="top"><img alt="" src="image/icone/apollogeneration2-1.jpg" width="145" /></td>

</tr>

</tbody>

</table>

</td>

<td align="right" class="sinistraB" valign="top" width="50%">

<table border="0" cellpadding="0" cellspacing="10" width="100%">

<tbody>

<tr>

<td align="left" valign="top">

<p class="titoloRosso">WHAT HAPPENS IF MY POULTRY SHED HAS PILLARS INSIDE?</p>

Thanks to the front-loading system and the different front head width sizes Apollo Gen2-B can easily move along different corridors.</td>

<td align="center" valign="top"><img alt="" height="144" src="image/icone/capannoned.jpg" width="101" /></td>

</tr>

<tr>

<td align="left" valign="top">

<p class="titoloRosso">WHAT IF IT gets very cold or VERY HOT?</p>

Apollo Gen2-B works very well between temperatures of -40° C (-40° F) and +50° C (122° F).</td>

<td align="center" valign="top"><img alt="" height="70" src="image/icone/temperatured.jpg" width="193" /></td>

</tr>

<tr>

<td align="left" valign="top">

<p class="titoloRosso">AND IN TERMS OF CLEANING?</p>

Following the EHEDG and CMC Cleanability Protocols the entire design of Gen2-B has been optimized and simplified to ensure a better access to all machine points and an easier cleanability of all components, resulting in a faster and more effective cleaning process and improved bio-security.</td>

<td align="center" valign="top"><img alt="" src="image/icone/termscleaning.jpg" width="90" /></td>

</tr>

</tbody>

</table>

</td>

</tr>

</tbody>

</table>

<p> </p>

<script>

// Funzione che rende i titoli tutti della stessa altezza

var maxHeight = -1;

$('ol.schedaDettagli li').each(function() {

maxHeight = maxHeight > $(this).height() ? maxHeight : $(this).height();

});

$('ol.schedaDettagli li').height(maxHeight);

</script>

the New Frontier. With blown air system.</p>

<p> </p>

<table border="0" cellpadding="0" cellspacing="0" width="960">

<tbody>

<tr>

<td>

<ol class="schedaDettagli">

<li><span>Load Quality</span><br />

Lower belts Speed. Wider belts. Smoother conveyoing. Gentle placement of the birds inside the containers. All resulted in better load quality with no compromises on loading speed.</li>

<li><span>Full focus on animal welfare</span><br />

<br />

Birds are loaded in a natural, stress-free manner, gently deposited into the drawers, with no direct contact from operators.</li>

<li><span>Addresses biosecurity issues</span><br />

<br />

The design has been optimized according to EHEDG (the European Hygienic Engineering and Design Group) guidelines. All components that come into contact with the birds are made out of either stainless steel or galvanized metal. Cages never come into contact with the litter.</li>

<li><span>Loading Speed</span><br />

<br />

From 8,000 to 12,000 animals per hour, or approximately 35,000-57,000 lb per hour.<br />

</li>

<li><span>Better working conditions for employees</span><br />

<br />

Easy to maneuver. Significant reduction in physical labour.</li>

<li class="liright"><span>Easy to clean</span><br />

<br />

Specifically designed to facilitate easy, quick and effective daily cleaning with only water and disinfectant with no compromises on biosecurity.</li>

<li class="liright"><span>Easy to use & Reduced Labor Cost</span><br />

<br />

Requires only 3-4 operators.Simple controls. Stable rubber tracks.Automatically loads birds to operator’s preset weight limit.</li>

<li class="liright"><span>Flexibility</span><br />

<br />

Loads any type of cage available in the US market.</li>

<li class="liright"><span>Durability & Reliability</span><br />

<br />

Designed on the field experience of more than 10Million working hours gained all-over the world</li>

<li class="liright"><span>Straightforward maintenance</span><br />

<br />

Clear and simple user manual, with explicit maintenance program outlined. Manual includes specific component breakdowns with diagrams of all parts. Easy access to core parts of the machine.</li>

</ol>

</td>

</tr>

</tbody>

</table>

<table border="0" cellpadding="0" cellspacing="0" class="domande" width="960">

<tbody>

<tr>

<td class="destraB">

<p class="titoloRosso"><strong>All the answers for your questions.</strong></p>

<p> </p>

<table border="0" cellpadding="0" cellspacing="10" width="100%">

<tbody>

<tr>

<td align="left" valign="top">

<p class="titoloRosso">IS APOLLO GENERATION 2 A QUALITY PRODUCT?</p>

Most definitely. With 40 years of experince and machines all over the world (over 90% market share wordwide) Apollo Gen2-B is the best solution to support your business. Apollo Gen2-B adheres to the strictest quality standards imposed by the leading food sector companies around the world.</td>

<td align="center" valign="top"><img alt="" src="image/icone/apollogeneration2.jpg" width="90" /></td>

</tr>

<tr>

<td align="left" valign="top">

<p class="titoloRosso">WHICH TYPES OF CONTAINERS CAN I USE?</p>

Any type. Apollo Gen2-B is suitable for the most common drawer systems and cages available on the market. The Apollo Gen2-B version has been optimized to work at its best in combination with the most common cages being used in the US market. Different types of containers can even be used during the same loading session: a simple computer setting is all that it takes.</td>

<td align="center" valign="top"><img alt="" src="image/icone/apollogeneration2-1.jpg" width="145" /></td>

</tr>

</tbody>

</table>

</td>

<td align="right" class="sinistraB" valign="top" width="50%">

<table border="0" cellpadding="0" cellspacing="10" width="100%">

<tbody>

<tr>

<td align="left" valign="top">

<p class="titoloRosso">WHAT HAPPENS IF MY POULTRY SHED HAS PILLARS INSIDE?</p>

Thanks to the front-loading system and the different front head width sizes Apollo Gen2-B can easily move along different corridors.</td>

<td align="center" valign="top"><img alt="" height="144" src="image/icone/capannoned.jpg" width="101" /></td>

</tr>

<tr>

<td align="left" valign="top">

<p class="titoloRosso">WHAT IF IT gets very cold or VERY HOT?</p>

Apollo Gen2-B works very well between temperatures of -40° C (-40° F) and +50° C (122° F).</td>

<td align="center" valign="top"><img alt="" height="70" src="image/icone/temperatured.jpg" width="193" /></td>

</tr>

<tr>

<td align="left" valign="top">

<p class="titoloRosso">AND IN TERMS OF CLEANING?</p>

Following the EHEDG and CMC Cleanability Protocols the entire design of Gen2-B has been optimized and simplified to ensure a better access to all machine points and an easier cleanability of all components, resulting in a faster and more effective cleaning process and improved bio-security.</td>

<td align="center" valign="top"><img alt="" src="image/icone/termscleaning.jpg" width="90" /></td>

</tr>

</tbody>

</table>

</td>

</tr>

</tbody>

</table>

<p> </p>

<script>

// Funzione che rende i titoli tutti della stessa altezza

var maxHeight = -1;

$('ol.schedaDettagli li').each(function() {

maxHeight = maxHeight > $(this).height() ? maxHeight : $(this).height();

});

$('ol.schedaDettagli li').height(maxHeight);

</script>

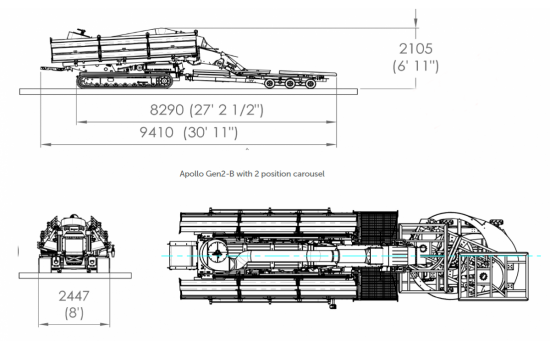

Technical data

MOTOR

Model: Kubota V2607-CR-T-E5B (Tier 5)Maximum power: 53 kW (71 Hp)

Revolutions per minute:

2,000 (Machine in use)

2,700 (max)

Functioning: 4 stroke turbo diesel

Cooling: liquid, hydraulic reversible fan

Number of cylinders: 4 in line

Cylinder capacity: 2,600 cc

Consumption: 1,58 - 1,84 gal/h

PERFORMANCE

Machine set-up time: 5 minutesOperators: 3-4

Load quantity: From 35,000 to 57,000 lb/h

Machine weight*: 17,637 lb

*Incl. two position Carousel and 9mt harvesting head.

ÜBERTRAGUNG

Double hydrostatic pump with variable cylinder capacity: 21cc + 21ccSelf-moving (at low and adjustable speed) during loading

Joystick-controlled (2 speed) movement

Electrohydraulic parking brake

Rubber tracks with internal steel structure width 450mm (173/4')

Tanken

Fuel tank: 93 l - 24,55 gHydraulic tank: 93 l - 24,55 g

SERIENAUSSTATTUNG

Harvesting head:from 3 to 9 mContainer carousel

Caging belt units with blown air system

Soft Start System: controls all the belts to gradually start, allowing the birds to keep their balance

Optionale E ZUBEHÖR

Hydraulic hitch for interchangeable headHydraulic oil for low temperature type ATF XT

WEITERE INFORMATIONEN

Frame: Hot-dip galvanised steel and stainless steelCleaning: High pressure air and water

Push Button: IP 69 K rating